CalciumSilicon Alloy Is A Composite

Our Service

Honesty and trustworthiness, treating customers with sincerity, establishing and maintaining good customer relationships

01

The Role of Silicon Calcium Alloy in Metallurgical Industry

Silicon calcium alloy is mainly used as a deoxidizer in the metallurgical industry. Its strong aerobic properties enable it to react with oxygen,

02

Especially in the process of steel smelting, the addition of silicon calcium alloy can effectively reduce the oxygen content in steel, improve the performance and quality of steel.

03

This specific composition endows silicon calcium alloys with unique properties and application value.

Calcium alloys have broad application prospects in the metallurgical industry

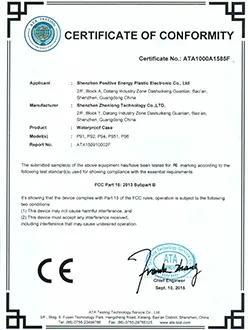

Certificate name

Certificate name

Certificate name

Certificate name

Certificate name

Certificate name

Our advantage

Choose the plan that suits you best.

Alloy additive

Silicon calcium alloy is used as an additive in the preparation process of some special alloys. It can form compounds with other metal elements, changing the crystal structure and plasticity of alloys.

from silicon calcium alloy has good high

Corrosion resistance and mechanical strength, widely used in industrial fields such as aviation, automotive, and shipbuilding.

Preparation of refractory materials

Silicon calcium alloys can also be used to prepare refractory materials, such as silicon calcium bricks.

Calcium silicate bricks have excellent fire resistance and thermal stability

and are widely used in high-temperature equipment and furnace lining in industries such as metallurgy, chemical industry, and building materials

Slag protector

Silicon calcium alloy can also be used as a slag protector, which is added to the melt during the smelting process to improve the properties of the slag

Silicon calcium alloy can react

Silicon calcium alloy can react with impurities in slag to generate substances that are easy to float, which helps to improve smelting efficiency and product purity.

Silicon calcium aluminum alloy

In modern metallurgical industry, silicon calcium alloy is usually used in conjunction with aluminum alloy to prepare silicon calcium aluminum alloy

This alloy has ultra-high strength

This alloy has ultra-high strength, good plasticity and corrosion resistance, and is widely used in high-tech fields such as aerospace and automotive manufacturing.

Membership Plans

Select destination

Set an itinerary

Set a return date

Apply for passport/visa

Foreign currency exchange

Telephone and Internet access

Select destination

Set an itinerary

Set a return date

Apply for passport/visa

Foreign currency exchange

Telephone and Internet access

Select destination

Set an itinerary

Set a return date

Apply for passport/visa

Foreign currency exchange

Telephone and Internet access

Select destination

Set an itinerary

Set a return date

Apply for passport/visa

Foreign currency exchange

Telephone and Internet access

Hot Tags: calciumsilicon alloy is a composite, China calciumsilicon alloy is a composite manufacturers, suppliers, Electrolytic Manganese Piece, Low sulfur And Low nitrogen Carburizer, Silicon Carbide, Ferromanganese, High Carbon Silicon Block, Ferrochrome For Steelmaking And Casting

Previous

No InformationYou Might Also Like

Send Inquiry